About Turboprop aircraft

Discover more about the characteristics that make each model unique. Additionally, visit the dedicated page for each variant to take part in a virtual tour of the interiors of ATR turboprop aircraft and cockpit.

Learn more about the highly-efficient technology behind turboprops, what they are, how the engine works, and in what contexts and environments they prove particularly useful.

What is a turboprop aircraft?

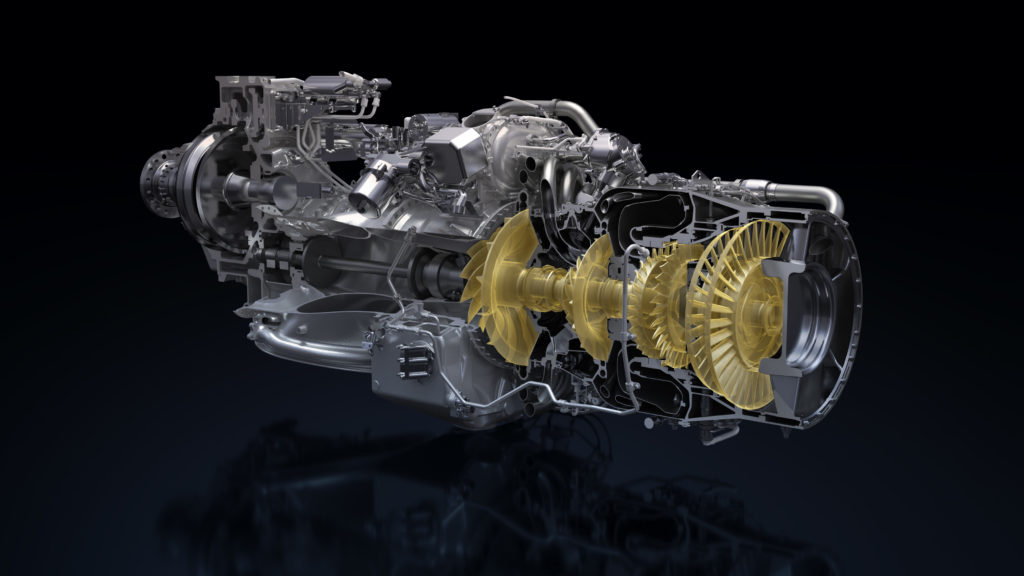

An aircraft engine is the beating heart of the plane, it’s where energy is produced. In turboprops, this energy is used to rotate a propeller. The air admitted in the engine is compressed to reach optimum pressure and temperature before being burnt with fuel in the combustion chamber. The pressure and the speed of the hot gases resulting from the combustion provide the force needed to turn the turbines and the shaft, which in return drives the propeller of the turboprop.

One of the standout features of turboprop engines is their fuel efficiency on short routes, which makes them the ideal regional aircraft. They also offer exceptional versatility, especially when it comes to utilising short runways. This capability is vital for regional and commuter aircraft that often need access to smaller airports with limited runway lengths.

In fact, an impressive statistic reveals that approximately 34% of airports globally rely exclusively on aircraft equipped with turboprop engines for their operations.

What are turboprops used for?

The versatility of ATR aircraft stands as a testament to their exceptional design and adaptability. Originally conceived as efficient regional passenger aircraft, ATR aircraft have seamlessly evolved to cater to a diverse range of aviation needs. Their modular design allows for swift transformations, enabling these aircraft to effortlessly transition from serving as passenger carriers to efficiently transporting cargo, or having a greater operational flexibility with the passenger-cargo “combi” version of the ATR 72-600. They can even accommodate VIP configurations like ATR Highline, ATR’s collection of high-end cabin interiors dedicated to air carriers seeking an unparalleled experience for guests. ATR’s commitment to versatility ensures that operators have the flexibility to tailor their fleets to dynamic market demands, offering a cost-effective solution for regional airlines, cargo operators, and other types of carriers. This adaptability not only underscores the economic viability of ATR aircraft but also positions them as a reliable choice across a spectrum of aviation requirements, showcasing the brand’s commitment to innovation and meeting the evolving needs of the aviation industry.

How does a turboprop engine work?

A turboprop engine operates on the principles of gas turbine propulsion and is commonly used in smaller and regional aircraft. Here’s a technical explanation of how it works:

- Air Intake: The process begins as the engine draws in ambient air through an intake.

- Compression: The incoming air is compressed by a series of axial or centrifugal compressors. This compression increases air pressure, preparing it for combustion.

- Combustion: Aviation fuel is injected into the high pressure, compressed air and ignited. This combustion process produces high– temperature, high– pressure gases.

- Gas Expansion: The rapidly expanding gases flow through a set of turbines. These turbines are connected to the compressor and power the entire engine cycle.

- Output Shaft: Unlike pure jet engines, the power generated by the turbines in a turboprop isn’t solely used for thrust. Instead, it’s transferred to an output shaft.

- Reduction Gearbox: The output shaft connects to a reduction gearbox, which reduces the high– speed rotation of the turbine to a suitable speed for driving a propeller.

- Propeller: The output from the reduction gearbox drives a multi blade propeller at the front of the engine. The spinning propeller accelerates a mass of air to the rear, generating thrust.

ATR Specifications Comparison

Performance

Weight & payload

Dimensions

| Models | ATR 42-600 | ATR 72-600 | ATR 72-600F (Freighter) |

|---|---|---|---|

|  |  |

|

| Take-off distance (MTOW, ISA, SL) | 1,107m | 1,315m | 1,315m |

| Landing distance (MLW, SL) | 966m | 915m | 915m |

| Range Max Pax | 726NM / 1345km | 740NM / 1370km | 1030NM / 1908km Range based on max volumetric payload |

| Brochures | Download | Download | Download |

| Models | ATR 42-600 | ATR 72-600 | ATR 72-600F (Freighter) |

|---|---|---|---|

|  |  |

|

| Take-off Distance MTOW, ISA, SL | 3,632ft | 4,314ft | 4,314ft |

| Landing Distance MLW, SL | 3,169ft | 3,002ft | 3,002ft |

| Range Max Pax | 726NM / 835mi | 740NM / 851mi | 1,030NM / 1,185mi Range based on max volumetric payload |

| Brochures | Download | Download | Download |

| Models | ATR 42-600 | ATR 72-600 | ATR 72-600F (Freighter) |

|---|---|---|---|

|  |  |

|

| Maximum Take-off Weight | 18,600kg | 23,000kg | 23,000kg |

| Maximum Landing Weight | 18,300kg | 22,350kg | 22,350kg |

| Maximum Zero Fuel Weight | 17,000kg | 21,000kg | 21,000kg |

| Maximum Payload | 5,250kg | 7,400kg | 9,200kg |

| Maximum Fuel Load | 4,500kg | 5,000kg | 5,000kg |

| Brochures | Download | Download | Download |

| Models | ATR 42-600 | ATR 72-600 | ATR 72-600F (Freighter) |

|---|---|---|---|

|  |  |

|

| Maximum Take-off Weight | 41,005lb | 50,706lb | 50,706lb |

| Maximum Landing Weight | 40,344lb | 49,272lb | 49,272lb |

| Maximum Zero Fuel Weight | 37,478lb | 46,296lb | 46,296lb |

| Maximum Payload | 11,574lb | 16,313lb | 20,281lb |

| Maximum Fuel Load | 9,920lb | 11,024lb | 11,024lb |

| Brochures | Download | Download | Download |

| Models | ATR 42-600 | ATR 72-600 | ATR 72-600F (Freighter) |

|---|---|---|---|

|  |  |

|

| Overall Length | 22.67m | 27.17m | 27.17m |

| Wingspan | 24.57m | 27.05m | 27.05m |

| Factsheets | Download | Download | Download |

| Models | ATR 42-600 | ATR 72-600 | ATR 72-600F (Freighter) |

|---|---|---|---|

|  |  |

|

| Overall Length | 74.38ft | 89.14ft | 89.14ft |

| Wingspan | 80.61ft | 88.75ft | 88.75ft |

| Brochures | Download | Download | Download |

90% common spare parts

The ATR 42 and ATR 72 series have the same fuselage cross section, use the same systems, share the same engines and propellers, as well as the same cockpit, allowing for common type rating or cross crew qualification (CCQ). This results in major cost savings for operators in terms of flight crew training and maintenance. Some 90% of the spare parts are common to both models.

Turbojet vs Turboprop

On regional routes turbo propellers are the most efficient engines burning twice less fuel than turbojets, because they have a different propulsion system from the turboprop: the energy created drives a propeller in return. Because of the large diameter propeller, they require less power, so less fuel to accelerate the air. The turboprop will burn up to 45% less fuel, and emit up to 45% less CO2

Superiority of propellers

Fly to any region of the world, no matter the weather

Thanks to their ability to fly in extreme cold (-45°C) and extreme hot (+50°C) temperatures, ATR aircraft can be operated in all regions of the world.

Reduce your CO2 emissions and your fuel consumption by up to 45% with ATR

ATR aircraft consume up to 45% less fuel and emit 45% less CO2 per trip than regional jets.

That’s 4,400 tonnes of CO2 saved per aircraft per year vs regional jets on average route of 300NM.

Why?

Because of the large diameter propeller they require less power, so less fuel to accelerate the air.

Get in touch

Please complete the form below to get in touch with us.